Optimization of the Transport Systems

In many industrial sectors, automation employs transport systems that allow the movement of products from one point of the plant to another.

In terms of production, this movements primarily concern the semi-finished products that must pass through the various processing steps, while in the logistics field, handling the goods is itself the industry's objective.

Linear transport by conveyor belt systems is one of the most widespread solutions for moving solid objects of various sorts and sizes.

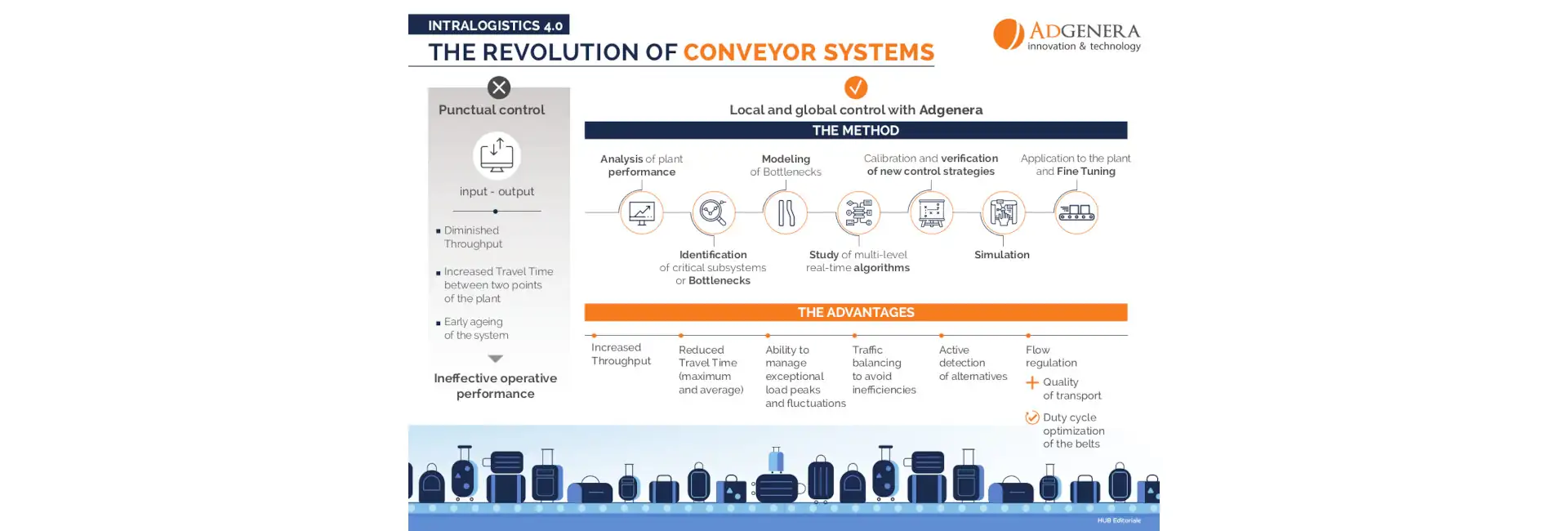

The Control System that is traditionally used consists of simple logical structures that operate locally with an "action-reaction" philosophy, based on the status of the photocells or proximity sensors placed directly on the belt and on other status data received from the subsequent transport elements.

As the complexity of the plant grows, however, the relationships between the various elements become extremely complex. Each intersection and confluence of belts becomes a source of inefficiency due to the need to coordinate the transfer of the transported products while avoiding collisions.

Just like a road network in a large city, local inefficiencies generate bottlenecks in the flow, which in turn cause obstructions or blockages.

Furthermore, the traditional approach is too rigid to automatically manage any malfunctions (stoppage of one or more belts) or exceptional loads from/to one or more destinations.

- Diminished Throughput

- Increased Travel Time between two points of the plant

- Early ageing of the system, caused by excessively frequent belt stopping and starting cycles

The traditional approach just described is no longer sustainable in the modern competitive environment.

For these reasons, the average operating performance of many plants is much lower than the nominal one, and as a result, they do not reach the productivity targets for which they were designed.

As an alternative to the expansion or renewal of the existing plant, it is possible to apply multi-level optimization techniques capable of correcting the inefficiencies due to the gap between the complexity of the transport system and the simplicity of the control logics, with incredible economic savings and without service interruptions.

- Analysis of current plant performance under the most representative working conditions

- Identification of critical subsystems (Bottlenecks)

- Modelling of these subsystems

- Study and assessment of multi-level real-time optimization algorithms

- Calibration and verification of new control strategies in a simulated environment

- Application to the plant and Fine Tuning

- Increased Throughput

- Reduced Travel Time (maximum and average)

- Ability to manage exceptional load peaks and fluctuations in the typical distribution of objects to be transported

- Traffic balancing to avoid blockages, stoppages, slowdowns and latencies

- Ability to react actively to the unavailability of one or more belts

- Flow regulation both in terms of quality of transport (positioning of objects carried on belts, gap between objects, alignment) and in terms of duty cycle of the belts (reduction of shutdown and restart events and, consequently, reduced stresses and wear).

Adgenera offers the Customer its specific experience in this type of interventions together with the ability to adapt the solution to the existing plant.